how blind rivets work

Open End Blind Rivets are for fastening where there is no access to the opposite side of work. Open End Blind Rivets are simple to install with either hand tools battery-powered tools and.

Robust Professional Blind Rivet Pliers Chrome Molybdenum 19 99

Once it meets the face of the joins blind side the.

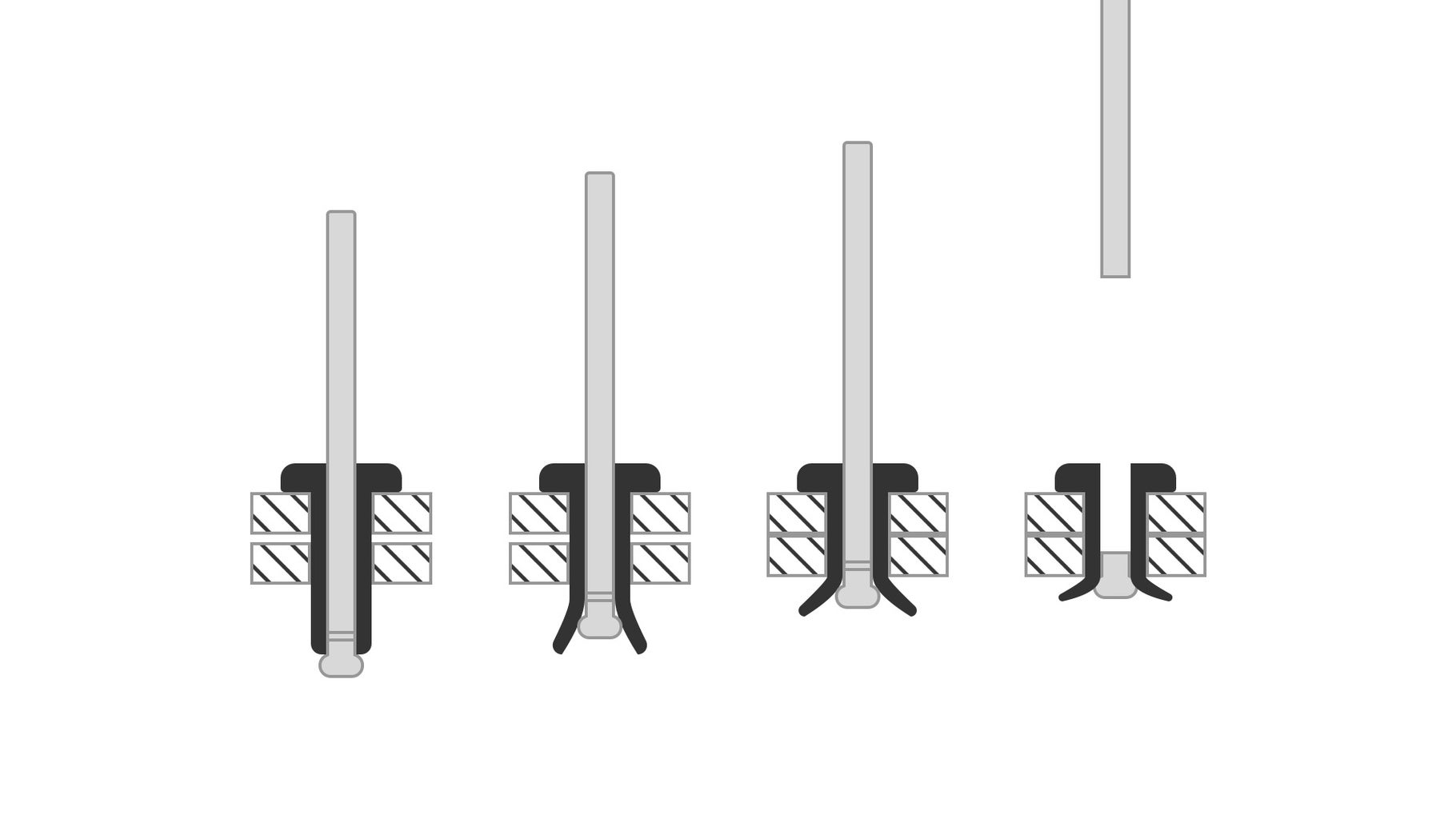

. Once gripped the mandrel snaps permanently holding the rivet. A riveter is used to pull the mandrel back while holding the rivet in. Blind rivets also commonly referred to as POP Rivets are mainly used in applications where there is no access to the rear blind side of the joint.

Not all blind fasteners. The blind rivet is a mechanical fastening element consisting of a bushing and a mandrel to be applied through a riveting toolBy placing the blind rivet into. Blind Rivets Reference.

The rivet is first placed into an installation tool and is. The sleeve of the nail is inserted through one side of a. Pop rivets are a relatively simple design consisting of a shank that is inserted into a pre-drilled hole and a mandrel that fits through the shank.

A pop rivet gun is placed on the rivet pulling the mandrel into the rivet body causing it to expand and grip the parts to be joined. If the hole is large enough you can mill out a chamber with a T-mill not very cost effective though. If you can undercut the blind hole then even better.

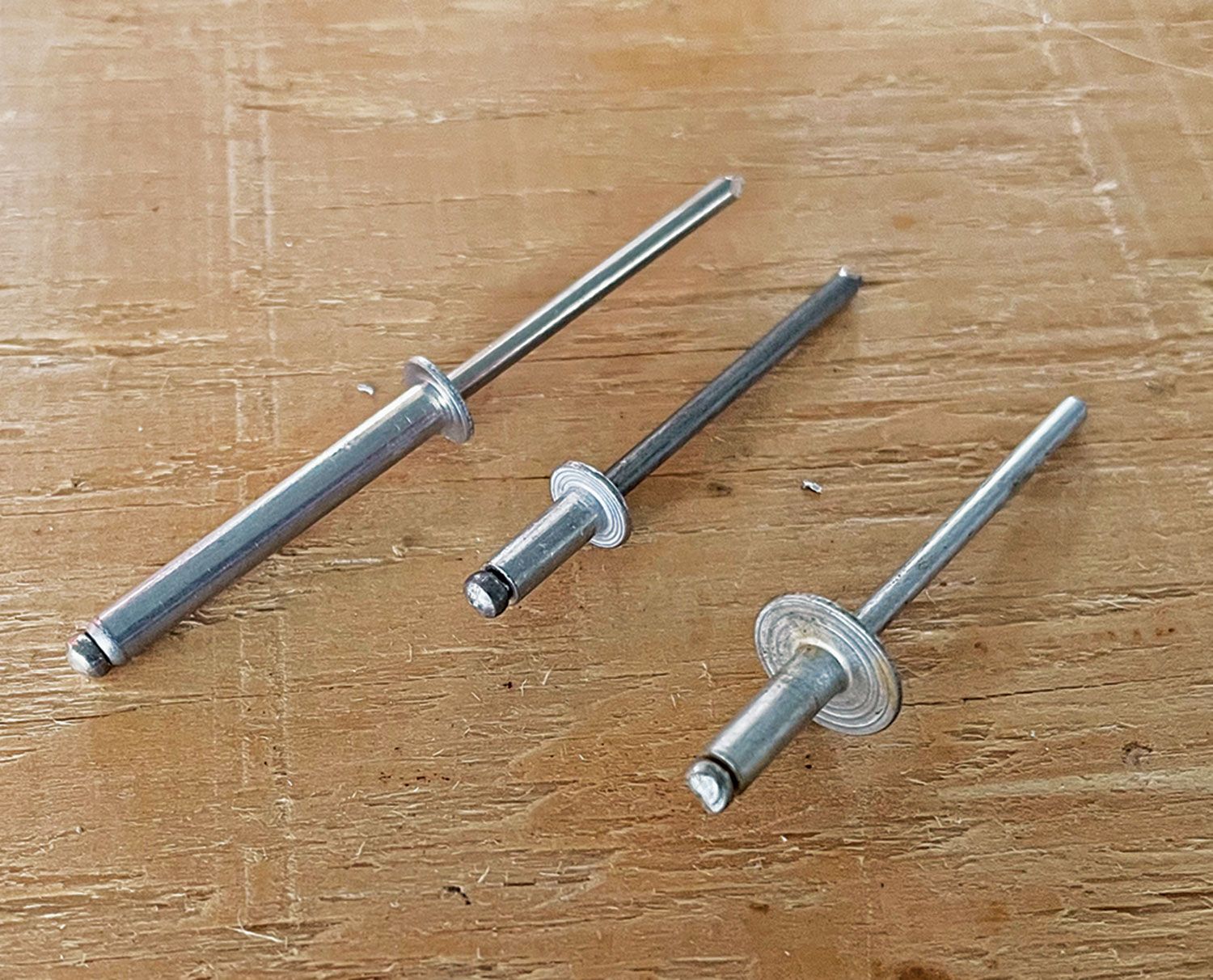

Rivets have a two-piece construction. When choosing a blind fastener its important to overcome these five common misconceptions. Blind rivets are installed in a tight hole that passes through the materials being riveted Step 1 2.

If the parts have been assembled in a way that prevents access to the back side blind rivets may be used to join them. How blind rivets work. In addition the aluminum and steel rivets can be supplied in all RAL colors.

The length of the rivet will change the grip range. Pop rivets would work fine though. All Blind Fasteners Are the Same.

The rivet pin which will pass through the pieces of material being linked together is the rivets primary. HOW BLIND RIVETS WORK The standard blind break-mandrel rivet is comprised of two components a rivet body and mandrel. During blind riveting the nail is positioned in a blind rivet tool.

A rivets grip range is the range of how thick the material can be for a. A special pop rivet gun or tool pulls the mandrel head into the body of the rivet which then expands against the blind side of the join. The back side of the parts is the blind side.

To install the rivet the mandrel is. The rivet diameter determines the size hole that needs to be drilled.

Nonthreaded Fasteners Cutting Tool Engineering

Blind Rivet Gun Ford Gm Compliant Gat Riv508 Fgm

Amazon Com 100 Pcs Large Flange Aluminum Pop Rivets 3 16 X 3 4 Big Head Steel Mandrel Dome Body Blind Rivets Set For Sheet Steel Duct Work Industrial Scientific

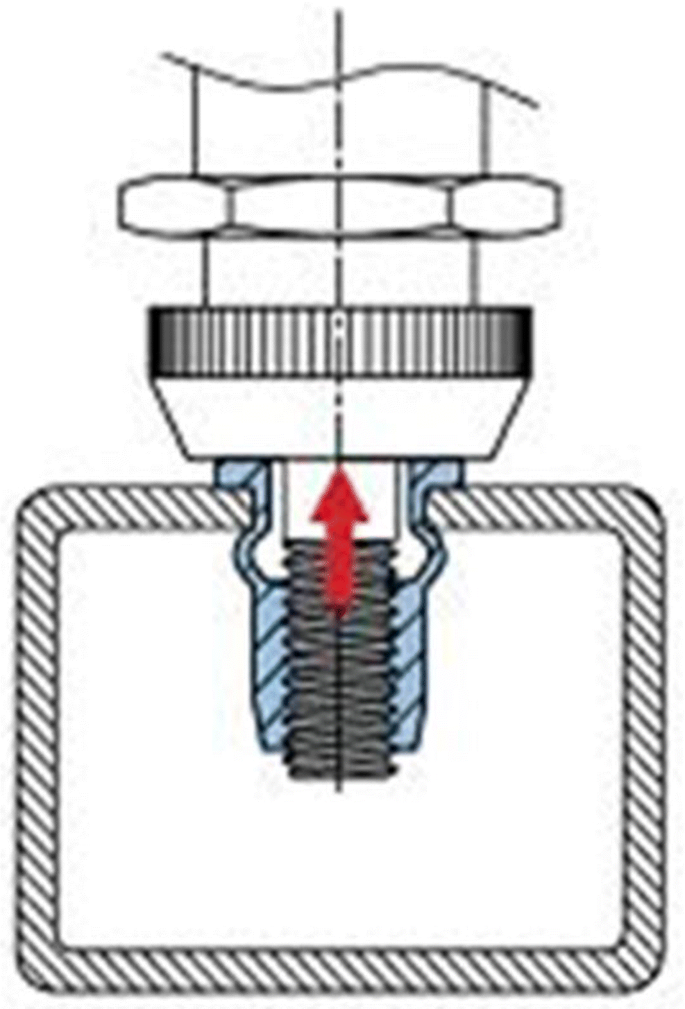

How Does A Blind Rivet Nut Work

What Is The Difference Between A Blind Bolt And A Blind Rivet Blindbolt Us

Understanding Rivet Tools For Various Applications Goebel Fasteners

4 Tips For Stronger Blind Rivet Joints Machine Design

Blind Rivets Look Closely Kitplanes

What Is A Pop Rivet And How Does It Work Engineering Choice

Blind Rivet Tools Jay Cee Sales And Rivet

What Are Structural Rivets Albany County Fasteners

Source Drive Rivets Rivet Nuts And Blind Rivets On M Alibaba Com

160 Pc Pop Riveter Gun Set Blind Rivet Hand Tool Kit Gutter Repair Heavy Duty 696449768320 Ebay

All About Pop Rivets 6 Steps Instructables

How Blind Fasteners Work Install In Less Than 2 Seconds

Towards Best Practice In Numerical Simulation Of Blind Rivet Nut Installation Springerlink

Blind Rivets How They Work And Why They Are Used In Airplanes Blog Monroe Aerospace